Generative and Multimodal AI to Address Drug Out-of-Stock Problems

Generative and Multimodal AI to Address Drug Out-of-Stock Problems

Drug stock-outs represent a major challenge for healthcare systems worldwide, endangering patients’ lives and compromising the quality of care. To address this crisis, generative and multimodal AI is emerging as an innovative and effective solution, capable of proactively preventing and managing these stock-outs. This article explores in depth the different facets of this problem and the solutions offered by AI.

Drug shortages on the rise: a disturbing situation

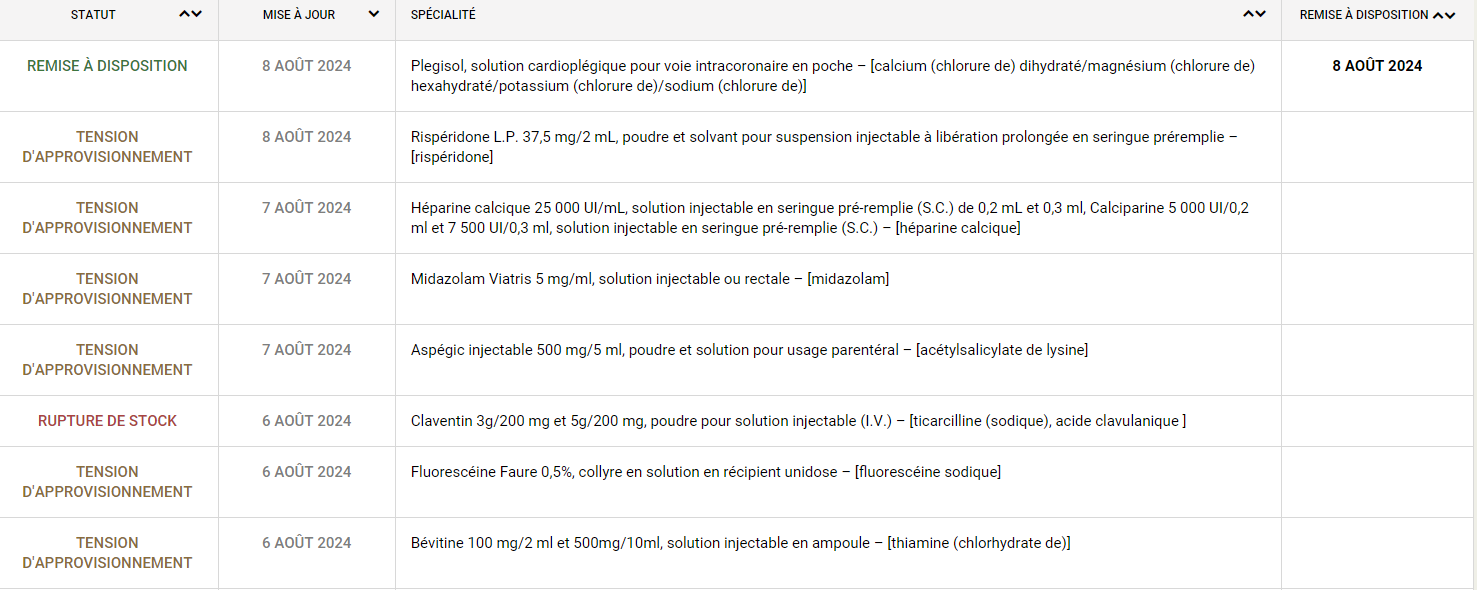

Drug stock-outs have become an increasingly frequent and worrying problem. In 2023, more than 4,925 drugs were reported to the French National Agency for the Safety of Medicines and Health Products (ANSM) as being in tension or out of stock. 2,446 reports of stock-outs and risks of stock-outs were also registered in 2020, compared with 1,504 in 2019. All drug classes are concerned, but among the drugs most affected are cardiovascular drugs, nervous system drugs, anti-infectives and anti-cancer drugs (L. Collet, 2023). This situation is alarming, as it compromises continuity of care and can have serious consequences for patients, including death, disease progression and hospitalization.

Types and causes of drug shortages

There are many reasons for stock-outs: production problems, increased demand, logistical difficulties and economic issues. The COVID-19 pandemic has exacerbated these tensions, highlighting the weaknesses of global supply chains. Drug stock-outs can be classified into several categories, each with specific and often complex causes:

- Production disruptions: Production disruptions occur when manufacturers are unable to produce enough drugs to meet demand. This can be due to technical problems, shortages of raw materials, or production stoppages for quality reasons. For example, contamination in a production line can bring manufacturing to a complete halt.

- Distribution disruptions:These are linked to logistical problems, such as delays in transport, storage problems or errors in inventory management. For example, delays in international shipments can lead to temporary shortages in certain regions.

- Economic disruptions: Economic disruptions occur when manufacturers decide to stop production of certain drugs deemed unprofitable. This is often the case for generic drugs, where profit margins are low.

- Regulatory disruptions:Regulatory changes can also lead to disruptions, particularly when drugs have to be withdrawn from the market for safety or compliance reasons. For example, changes in safety standards can force manufacturers to reformulate their products, resulting in production delays.

Impact of Generative and Multimodal AI on Inventory Management and Breakage Prevention

Generative and multimodal AI offer promising solutions for anticipating and preventing drug stock-outs. Using advanced algorithms and predictive models, these technologies can analyze large datasets to identify trends and anomalies.

Generative AI uses models such as generative adversarial neural networks (GANs) to create accurate simulations of supply chains. These models can generate new supply chain configurations, forecast demand variations and adjust strategies accordingly. By analyzing past sales data, seasonal trends, demographics and global events, generative AI can propose action plans to avoid drug shortages.

L’IA multimodale, quant à elle, intègre des informations provenant de multiples sources telles que les dossiers de santé électroniques, les registres de production, les rapports de vente et même les réseaux sociaux. Cette capacité à traiter et à comprendre des données variées permet une analyse plus complète et précise des situations. For example, by correlating spikes in online searches for certain symptoms with increases in sales of specific drugs, multimodal AI can help predict surges in demand even before they become clear in sales data.

We can cite the example of IBM Watson, which uses AI to analyze production and distribution data, helping manufacturers to anticipate stock-outs. In 2020, this technology enabled a major pharmaceutical company to reduce out-of-stocks by 20%.

“As hospitals around the world face a shortage of life-saving treatments, there is an immediate and critical need for evidence-based information about clinical alternatives,” said Todd Nolen, general manager of IBM’s Micromedex solutions, IBM Watson Health. “We are addressing this critical need by combining our Micromedex content with the powerful information of the OrbitalRX platform. Our goal is to provide a reliable platform to help pharmacists and other healthcare providers streamline workflow and respond quickly to drug shortages with appropriate, safe and effective alternative therapies.”

Optimizing Inventory and Supply Management with AI

Generative and multimodal AI not only predicts stock-outs, it can also optimize inventory and supply management in real time. Using natural language processing (NLP) and computer vision techniques, AI can analyze complex documents and propose appropriate solutions.

Automation and Increased Efficiency

One of the key benefits of AI in inventory management is the automation of manual processes. Traditionally, inventory management has relied on manual processes and often inflexible ERP (Enterprise Resource Planning) systems. AI, on the other hand, can automate data collection and analysis, reducing human error and increasing operational efficiency.

For example, AI systems can continuously monitor stock levels in warehouses, automatically triggering replenishment orders when a critical threshold is reached. This helps maintain optimal stock levels, avoiding both costly overstocking and dangerous shortages. Blue Yonder, a leading provider of supply chain solutions, has launched Blue Yonder Orchestrator, a generative AI technology that enables companies to make smarter decisions and accelerate supply chain orchestration, by combining large language models (LLMs), cloud data and prompt engineering.

Predictive Analysis and Preventive Maintenance

Generative and multimodal AI excels in predictive analysis, using algorithms to forecast future drug requirements based on historical trends and real-time data. This capability is particularly useful for drugs whose demand may fluctuate according to seasons, epidemics or other external factors.

Supply chain optimization

Supply chain management is another area where AI can make significant improvements. By integrating data from a variety of sources – including suppliers, carriers and distributors – AI can provide an overview of the supply chain, identifying bottlenecks and proposing solutions to resolve them.

Optimization algorithms can help plan the most efficient delivery routes, reducing transport times and costs. In addition, AI can analyze weather conditions, political events and other external factors likely to affect the supply chain, enabling managers to make informed decisions and minimize risks.

Despite its promise, the adoption of generative and multimodal AI in medication inventory management is not without its challenges. Data confidentiality is a major issue in the implementation of generative and multimodal AI, and the complexity of technological integration and the need for specialized training for healthcare professionals are all barriers to be overcome.